Mold design and press process

- HOME

- Our business

- Mold design and press process

Press working

From mold design to processing.

Press process

Our sales staff in charge responds in detail to the drawings consulted by our customers. we have a system for various needs.

After select materials, sub-materials, designing dies, and selecting the most suitable processing machines, we start the press process in response to the specifications and drawing requests.

We also check the quality using various inspection equipment under thorough quality control.

Features of press processing

We can handle from die design to press process.

We can handle more than 10,000 materials, including original products.

Proposals according to the way of use, purpose, and cost.

Flow of press process

01 Mold design

-

Hearing customers requests in detail.

-

Propose the optimal mold for the part, shape, and material.

-

Design mold through the prototyping process to mass production.

02 Processing

-

Processing with the designed mold

(full cutting, half cutting) -

-

Roll processing

Materials: film, double-sided tape.

Laminating of materials is possible at the same time.

Roll processing equipment -

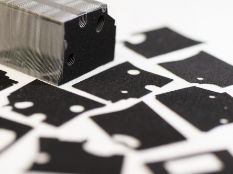

Sheet processing

Material: Elastic material

Sheet processing equipment

-

03 Inspection

-

Dimensional and

visual inspections

are performed and deliver.

Dimensional

measurement inspection

Appearance Inspection -

Delivery

About materials we handle

Vel-Suede always has a wide variety of materials available, including original materials.

By combining a wide variety of materials, it is possible to meet a wide range of applications.

We will be happy to consult with you on various aspects including cost and delivery time to meet your needs.

Main materials we handled |

|

|---|---|

Flocky Sheet |

RON-SUEDE A, RON-SUEDE SA, RON-SUEDE SAC, RON-SUEDE WA, RON-SUEDE S-LOG |

Film type |

Light-shielding PET film, PET film, polycarbonate, polyimide |

Rubber and elastomer |

Silicon rubber, CR rubber, EPDM, butyl rubber, polyurethane |

Foam materials |

Poron (INOAC), Rubber sponge, Moltoprene, Urethane sheet, etc. |

Artificial leather |

EXCÉNE (Toray), VELLSKIN |

Double-sided adhesive tapes |

PET base material, non-woven fabric base material, special base material, base material-less, functional tape |

Single coated tapes |

PET base material, paper base material, micro adhesive tape, protective tape |

Release paper |

PET separator, paper separator |

Other High Functional Materials |

Heat dissipation sheets, shielding electromagnetic wave materials, light-reducing (ND) filters, gel materials, sliding materials, gaskets |

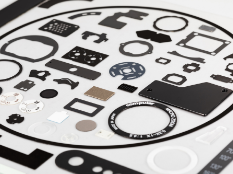

Anti-reflection ・Shade parts

Sponges ・Rubber parts

Heat dissipation sheets, shielding electromagnetic wave materials, gaskets, imitation leather

Silk printing・Original printing samples

Double-sided tape ・Decorative tape parts

Light-shielding film parts