Electrostatic flocking(flocking)

- HOME

- Our business

- Electrostatic flocking(flocking)

Vel-Suede's Electrostatic flocky (flocking) is

more than 99% anti-reflective.

Comparison of reflectance with Electrostatic flocky (flocking)

This video shows Comparison of reflectance when light is shone on Vel-Suede's electrostatic flocking sheet and other materials.

The rightmost one is Vel-Suede's electrostatic flocking sheet (Ron-suede SA0.5), which can prevent more than 99% of reflections compared to other materials.

Vel-Suede's Electrostatic flocky (flocking)

Electrostatic flocking is a technology that uses static electricity to fix cut fibers to adhesive-coated base materials such as film, paper, cloth, rubber, and molded products.

Vel-Suede's electrostatic flocking can be applied directly to sheet materials or molded products. These products are widely used in optical equipment, cosmetics, and decorative products.

Electrostatic flocky (flocking)

Vel-Suede's Electrostatic flocky (flocking) sheets are available in several lineups, including a specially treated product that prevents flocky pile falling off.

In addition to anti-reflective effects, they also provide dustproofing, heat insulation, drip-proofing, soundproofing, sliding, cushioning, and various other effects.

Features of Vel-Suede's Electrostatic flocky (flocking) sheets

Anti-reflection rate is over 99% and have ability to absorb light.

Excellent chemical resistance and weather resistance, and resistance to deterioration over time.

Double-sided tape can be applied to the back side, and press punching is also possible.

| Flocked Sheet Series | ||

|---|---|---|

| Product name | Thickness | Remark |

| RON-SUEDE A | 0.30mm・0.50mm | Film base material, flocky fall prevention treatment |

| RON-SUEDE SA | 0.30mm・0.50mm 0.80mm・1.00mm・1.20mm・1.50mm |

Film base material, flocky fall prevention treatment Film base material (Ron-suede SAC flocky fall prevention treatment) |

| RON-SUEDE WA | 0.30mm・0.50mm | No base material, flocky fall prevention treatment |

| RON-SUEDE S-LOG |

0.30mm・0.50mm | Film material, flocky fall prevention treatment, low outgassing |

How Electrostatic flocky (flocking) Work

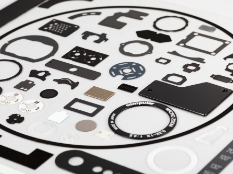

Flocking of molded products

Electrostatic flocking is applied to metal, plastic, rubber, and other molded parts to give them functionality.

It is also used for decorative purposes.

Main applications

Lens hoods, prevention of diffused reflection in optical equipment, sliding parts

Heat insulation and burn prevention for copy machine, etc.

Automobiles (HUD, ADAS, etc.), air conditioners

Waterproofing and shock-absorbing of construction materials

Decoration of cosmetic cases, postcards, etc.

Automobile integrated cockpit area

(HUD, ADAS)

Lens hoods for cameras

Thermal insulation covers for copy machines, etc.

Automobile interior parts (glove box, console box, etc.)

Parts for office automation equipment (high heat-resistant fiber electrostatic plastering)

Cosmetics bottle

Application example utilizing

the light absorption properties of electrostatic flocking

Vel-Suede's electrostatic flocking sheets are used as backgrounds for textile videos. By placing the electrostatic flocking sheets in the background of the textile and filming, a light-shielding effect is achieved, giving the impression of a 3D image of an object floating in midair.

(Presented by TEXTILE ART AND DIRECTED BY YOSHIKI HISHINUMA)